Unlocking Efficiency: The Role of Aluminum Alloy Bell Housings in Hydraulic Systems

Release Time:

Jun 22,2025

Unlocking Efficiency: The Role of Aluminum Alloy Bell Housings in Hydraulic Systems Table of Contents 1. Introduction to Aluminum Alloy Bell Housings 2. The Importance of Hydraulics in Modern Industry 3. What are Aluminum Alloy Bell Housings? 3.1. Definition and Structure 3.2. Advantages of Aluminum Alloys 4. The Role of Aluminum Alloy Bell Housings in Hydraulic Systems 4.1. Enhancing System Effic

Unlocking Efficiency: The Role of Aluminum Alloy Bell Housings in Hydraulic Systems

Table of Contents

1. Introduction to Aluminum Alloy Bell Housings

2. The Importance of Hydraulics in Modern Industry

3. What are Aluminum Alloy Bell Housings?

3.1. Definition and Structure

3.2. Advantages of Aluminum Alloys

4. The Role of Aluminum Alloy Bell Housings in Hydraulic Systems

4.1. Enhancing System Efficiency

4.2. Weight Reduction and Its Impact

5. Applications of Aluminum Alloy Bell Housings

5.1. Industrial Machinery

5.2. Automotive Systems

5.3. Aerospace Applications

6. Innovations in Manufacturing Aluminum Bell Housings

6.1. Advanced Casting Techniques

6.2. Surface Treatments for Durability

7. Challenges and Solutions in Using Aluminum Alloy Bell Housings

7.1. Thermal Conductivity Issues

7.2. Corrosion Resistance

8. FAQs about Aluminum Alloy Bell Housings in Hydraulic Systems

9. Conclusion

1. Introduction to Aluminum Alloy Bell Housings

In the realm of hydraulic systems, efficiency and reliability are paramount. Among the various components that contribute to these attributes, **aluminum alloy bell housings** have emerged as indispensable. Their unique properties and design characteristics make them a preferred choice in a wide array of applications, from industrial machinery to automotive systems. This article explores how aluminum alloy bell housings enhance the performance of hydraulic systems and the innovations driving their development.

2. The Importance of Hydraulics in Modern Industry

Hydraulic systems are the backbone of many industrial processes. They enable machines to perform heavy lifting, precise movements, and rapid power transmission with minimal effort. As industries continue to advance, the demand for efficient hydraulic systems has never been higher. The integration of high-quality components, such as aluminum alloy bell housings, plays a crucial role in meeting this demand, ensuring operational efficiency, reliability, and longevity.

3. What are Aluminum Alloy Bell Housings?

3.1. Definition and Structure

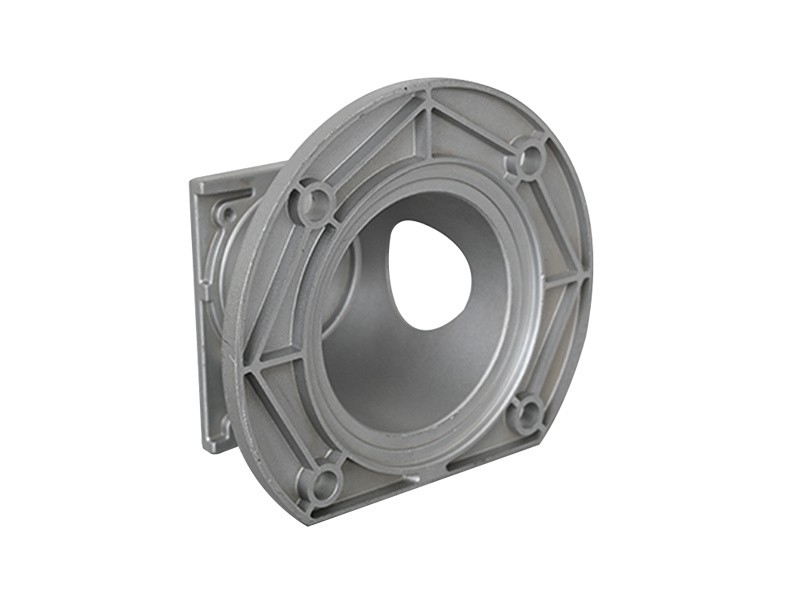

Aluminum alloy bell housings are specially designed enclosures that protect and support hydraulic components, such as pumps and motors. They typically feature a bell-shaped structure, which allows for optimal space utilization and effective load distribution. This design not only enhances the aesthetic appeal but also contributes to the overall performance of the hydraulic system.

3.2. Advantages of Aluminum Alloys

Aluminum alloys are known for their exceptional strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. These properties make aluminum alloy bell housings an ideal choice for hydraulic systems, as they can withstand high pressures and temperatures while remaining lightweight. Furthermore, aluminum is recyclable, making it an environmentally friendly option for manufacturers and end-users alike.

4. The Role of Aluminum Alloy Bell Housings in Hydraulic Systems

4.1. Enhancing System Efficiency

One of the primary advantages of using aluminum alloy bell housings in hydraulic systems is their ability to enhance overall efficiency. The lightweight nature of aluminum reduces the energy required to operate hydraulic components, which can lead to significant energy savings over time. Additionally, the excellent thermal conductivity of aluminum helps dissipate heat generated during operation, preventing overheating and ensuring optimal performance.

4.2. Weight Reduction and Its Impact

Weight reduction is a critical factor in the design of hydraulic systems, especially in applications where mobility and speed are essential. By incorporating aluminum alloy bell housings, manufacturers can significantly decrease the weight of hydraulic assemblies without compromising strength. This reduction not only improves maneuverability but also leads to lower fuel consumption in mobile applications, further enhancing efficiency.

5. Applications of Aluminum Alloy Bell Housings

The versatility of aluminum alloy bell housings makes them suitable for a wide range of applications across various industries.

5.1. Industrial Machinery

In industrial settings, aluminum alloy bell housings are commonly used in hydraulic presses, injection molding machines, and conveyor systems. Their ability to withstand harsh environments while providing reliable support for hydraulic components makes them a staple in these applications.

5.2. Automotive Systems

The automotive industry relies heavily on hydraulic systems for functions such as braking, steering, and suspension. Aluminum alloy bell housings are increasingly being used in these systems due to their lightweight properties and resistance to corrosion, contributing to improved vehicle performance and fuel efficiency.

5.3. Aerospace Applications

In aerospace, where weight is a critical factor, aluminum alloy bell housings are favored for their strength and lightweight characteristics. They are utilized in hydraulic systems that control aircraft movements, ensuring safety and reliability during flight operations.

6. Innovations in Manufacturing Aluminum Bell Housings

The manufacturing process for aluminum alloy bell housings has evolved significantly, driven by technological advancements and the need for enhanced performance.

6.1. Advanced Casting Techniques

Modern casting techniques, such as **die casting** and **sand casting**, allow manufacturers to produce aluminum bell housings with intricate designs and precise dimensions. These methods not only improve production efficiency but also enhance the mechanical properties of the final product, ensuring durability and reliability.

6.2. Surface Treatments for Durability

To further enhance the performance of aluminum alloy bell housings, manufacturers often apply advanced surface treatments. Processes like **anodizing** and **powder coating** improve corrosion resistance and wear characteristics, extending the lifespan of bell housings in demanding environments.

7. Challenges and Solutions in Using Aluminum Alloy Bell Housings

Despite their numerous advantages, aluminum alloy bell housings face certain challenges that manufacturers must address.

7.1. Thermal Conductivity Issues

While aluminum's thermal conductivity is generally beneficial, excessive heat can lead to structural integrity issues. Proper thermal management strategies, such as incorporating heat sinks or optimizing the design for airflow, can mitigate these risks and ensure consistent performance.

7.2. Corrosion Resistance

Aluminum is susceptible to corrosion, particularly in the presence of moisture and various chemicals. Employing surface treatments and protective coatings can significantly enhance corrosion resistance, making aluminum alloy bell housings suitable for a broader range of applications.

8. FAQs about Aluminum Alloy Bell Housings in Hydraulic Systems

1. What are the main benefits of using aluminum alloy bell housings?

**Aluminum alloy bell housings offer a lightweight design, high strength, excellent corrosion resistance, and improved thermal conductivity, contributing to enhanced efficiency in hydraulic systems.**

2. How do aluminum bell housings compare to steel bell housings?

**Aluminum bell housings are significantly lighter than steel, which reduces the overall weight of hydraulic assemblies. They also provide better corrosion resistance but may not withstand extreme pressures as effectively as steel in certain applications.**

3. Are aluminum alloy bell housings suitable for high-temperature applications?

**Yes, aluminum alloy bell housings can be used in high-temperature applications, provided that proper thermal management practices are implemented to prevent overheating.**

4. How do manufacturers ensure the quality of aluminum bell housings?

**Manufacturers use advanced casting techniques and rigorous quality control measures, including testing for structural integrity and performance under various conditions, to ensure the quality of aluminum bell housings.**

5. What industries utilize aluminum alloy bell housings?

**Aluminum alloy bell housings are widely used in industries such as manufacturing, automotive, aerospace, and construction, where reliability and efficiency in hydraulic systems are crucial.**

9. Conclusion

Aluminum alloy bell housings play an essential role in optimizing the performance of hydraulic systems across a variety of industries. Their lightweight design, superior strength, and excellent corrosion resistance make them an ideal choice for manufacturers seeking to enhance efficiency and reliability. As innovations in manufacturing and surface treatments continue to emerge, the future of aluminum alloy bell housings in hydraulic systems looks promising, paving the way for even greater advancements in industrial applications. Embracing these technologies not only benefits manufacturers but also contributes to more sustainable practices in the industry.

Keywords:

You Can Also Learn More About Industry Trends