Understanding the Essential Role of KTR Couplings in Industrial Equipment

Release Time:

Jun 26,2025

Understanding the Essential Role of KTR Couplings in Industrial Equipment Table of Contents 1. Introduction to KTR Couplings 2. What are KTR Couplings? 3. Types of KTR Couplings 3.1 Rigid Couplings 3.2 Flexible Couplings 3.3 Torsionally Rigid Couplings 4. Applications of KTR Couplings in Industry 5. Advantages of Using

Understanding the Essential Role of KTR Couplings in Industrial Equipment

Table of Contents

- 1. Introduction to KTR Couplings

- 2. What are KTR Couplings?

- 3. Types of KTR Couplings

- 4. Applications of KTR Couplings in Industry

- 5. Advantages of Using KTR Couplings

- 6. Selection Criteria for KTR Couplings

- 7. Installation and Maintenance of KTR Couplings

- 8. Common Issues with KTR Couplings and Solutions

- 9. Conclusion

- 10. Frequently Asked Questions

1. Introduction to KTR Couplings

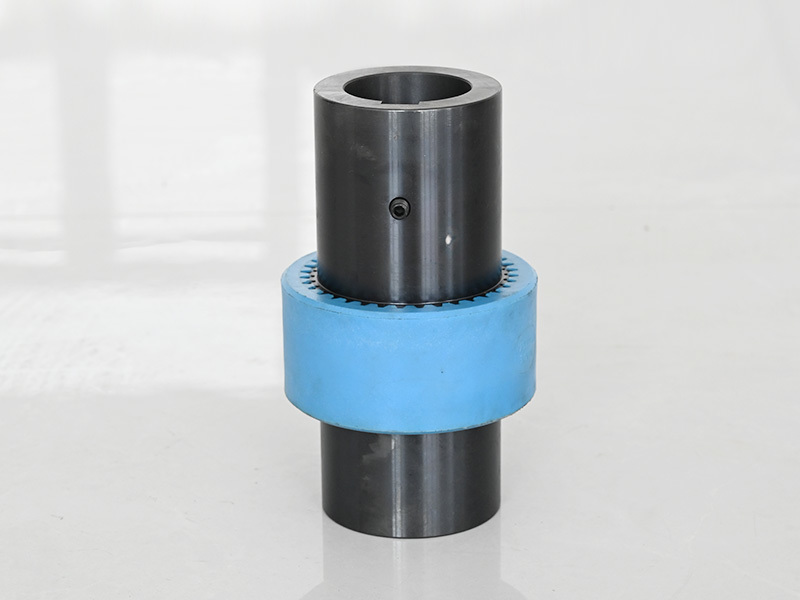

KTR couplings are vital components in the realm of industrial equipment, serving as a bridge between two rotating shafts. Their primary function is to connect these shafts while allowing for flexibility and accommodating misalignment. As industries evolve, the demand for reliable and efficient couplings has markedly increased, making KTR couplings an essential part of mechanical systems.

2. What are KTR Couplings?

KTR couplings are specialized mechanical devices designed to transmit torque and rotational motion between shafts. Engineered with precision, these couplings are known for their ability to compensate for misalignment, reduce vibrations, and absorb shock loads. KTR, a reputable manufacturer, offers a range of couplings that cater to various industries, including automotive, aerospace, and manufacturing.

Key Features of KTR Couplings

- **High Torque Capacity:** KTR couplings can handle significant torque loads, making them suitable for heavy-duty applications.

- **Versatility:** With multiple designs available, KTR couplings can be used in various mechanical setups.

- **Durability:** Constructed from high-quality materials, these couplings exhibit excellent wear resistance and longevity.

3. Types of KTR Couplings

KTR offers several types of couplings, each designed for specific applications and environmental conditions. Understanding these types is crucial for selecting the right coupling for your industrial needs.

3.1 Rigid Couplings

Rigid couplings are designed to connect two shafts securely without any flexibility. They are ideal for applications where precise alignment is critical. Their construction allows for the direct transmission of torque, ensuring minimal energy loss. Typically used in pumps and gear drives, rigid couplings provide a robust solution for industrial applications.

3.2 Flexible Couplings

Flexible couplings are designed to accommodate shaft misalignment and vibrations. They are particularly useful in applications where the shafts may not be perfectly aligned due to installation errors or thermal expansion. KTR's flexible couplings often feature elastic elements that can absorb shocks and reduce wear on connected components.

3.3 Torsionally Rigid Couplings

Torsionally rigid couplings are engineered to transmit torque without any angular deflection. These couplings are ideal for high-speed applications where stability and precision are paramount. KTR's torsionally rigid couplings ensure optimal performance in demanding industrial environments.

4. Applications of KTR Couplings in Industry

KTR couplings find application across various sectors, including:

- **Manufacturing:** Used in conveyor systems, robotic arms, and assembly lines where precision and reliability are crucial.

- **Automotive:** Integral in powertrains, drivetrain assemblies, and electric motor systems.

- **Aerospace:** Employed in aircraft engines and auxiliary systems, where performance and safety are non-negotiable.

- **Marine:** Utilized in propulsion systems and other critical components in marine vessels.

- **Renewable Energy:** Essential in wind turbines and other renewable energy systems, enhancing efficiency and longevity.

5. Advantages of Using KTR Couplings

KTR couplings offer numerous benefits that contribute to their widespread use in industrial applications:

- **Enhanced Efficiency:** By minimizing energy loss during torque transmission, KTR couplings ensure optimal performance.

- **Reduced Maintenance Costs:** Their durability and resistance to wear reduce the frequency and cost of maintenance.

- **Improved Safety:** Couplings that effectively absorb shocks and vibrations contribute to a safer working environment by preventing equipment failure.

- **Adaptability:** KTR couplings can be customized to meet specific requirements, making them suitable for a diverse range of applications.

6. Selection Criteria for KTR Couplings

Choosing the right KTR coupling involves evaluating several key factors:

- **Torque Requirements:** Determine the maximum torque that will be transmitted to select a coupling with an appropriate torque rating.

- **Shaft Alignment:** Assess the degree of misalignment between shafts to select a coupling that can accommodate this condition.

- **Environmental Factors:** Consider the operating environment, including temperature, humidity, and exposure to chemicals, to ensure the coupling's material is suitable.

- **Speed Requirements:** Evaluate the rotational speed of the shafts to determine if the coupling can handle high-speed applications.

7. Installation and Maintenance of KTR Couplings

Proper installation and maintenance are crucial for the longevity and performance of KTR couplings.

Installation Guidelines

- **Alignment:** Ensure that the shafts are properly aligned before installing the coupling to avoid premature wear.

- **Torque Specifications:** Follow manufacturer guidelines for torque specifications during installation to prevent damage to the coupling.

- **Cleaning:** Ensure that the shafts and coupling surfaces are clean and free of debris before installation.

Maintenance Tips

- **Regular Inspections:** Conduct periodic inspections to identify signs of wear or damage early.

- **Lubrication:** Follow recommended lubrication practices to ensure smooth operation and prevent overheating.

- **Replacement:** Replace couplings that show significant wear or damage to maintain operational safety.

8. Common Issues with KTR Couplings and Solutions

Even with their robust design, KTR couplings may encounter some common issues:

- **Excessive Vibration:** This can result from misalignment or imbalance in the connecting shafts. To resolve this, realign the shafts and ensure balanced loading.

- **Overheating:** Caused by inadequate lubrication or excessive load. Check lubrication levels and avoid overloading the coupling.

- **Wear and Tear:** Regular use may lead to wear over time. Schedule routine inspections and replace couplings when necessary to maintain performance.

9. Conclusion

KTR couplings play a pivotal role in enhancing the efficiency and reliability of industrial equipment. Their versatile designs cater to a wide range of applications, ensuring optimal performance in various sectors. By understanding the types of KTR couplings, their applications, and maintenance requirements, industry professionals can make informed decisions to improve their mechanical systems. Investing in KTR couplings means investing in longevity, efficiency, and safety for your industrial operations.

10. Frequently Asked Questions

1. What type of KTR coupling is best for high-speed applications?

Torsionally rigid couplings are ideal for high-speed applications due to their ability to transmit torque without angular deflection.

2. How often should KTR couplings be inspected?

Regular inspections should be conducted every few months, or more frequently in high-load or critical applications, to ensure optimal performance.

3. Can KTR couplings accommodate misalignment?

Yes, flexible KTR couplings are specifically designed to accommodate misalignment without compromising performance.

4. What is the expected lifespan of KTR couplings?

The lifespan of KTR couplings can vary based on usage, maintenance, and operating conditions, but with proper care, they can last many years.

5. Where can I purchase KTR couplings?

KTR couplings can be purchased through authorized distributors, online industrial equipment suppliers, and directly from KTR's official website.

This comprehensive article provides valuable insights into KTR couplings, ensuring that readers gain a clear understanding of their critical role in industrial equipment.

Keywords:

You Can Also Learn More About Industry Trends