Why Choose Aluminum Alloys for Your Hydraulic System's Bell Housing?

Release Time:

Jul 02,2025

Why Choose Aluminum Alloys for Your Hydraulic System's Bell Housing? Hydraulic systems are integral to a variety of industries, including automotive, aerospace, and manufacturing. A critical component of these systems is the **bell housing**, which serves multiple essential functions. One of the most pressing decisions engineers and designers face is selecting the right material for the bell housi

Why Choose Aluminum Alloys for Your Hydraulic System's Bell Housing?

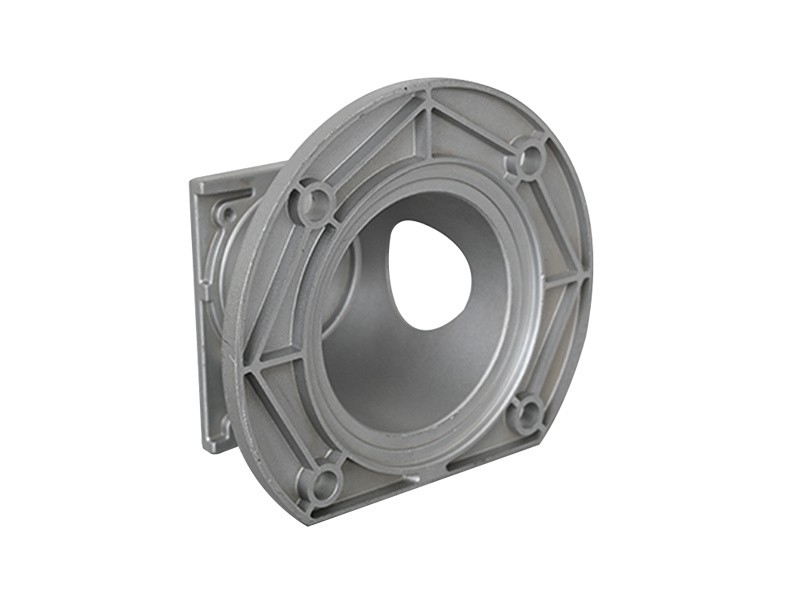

Hydraulic systems are integral to a variety of industries, including automotive, aerospace, and manufacturing. A critical component of these systems is the **bell housing**, which serves multiple essential functions. One of the most pressing decisions engineers and designers face is selecting the right material for the bell housing. In this article, we will delve into why **aluminum alloys** are the preferred choice for hydraulic system bell housings, outlining the numerous benefits they offer over traditional materials.

The Role of Bell Housing in Hydraulic Systems

Before exploring the advantages of aluminum alloys, it’s crucial to understand the function of bell housing within hydraulic systems. The bell housing is designed to enclose components such as the hydraulic pump and motor. It provides a protective barrier, aids in vibrations reduction, facilitates heat dissipation, and ensures proper alignment between the connected parts.

Key Functions of Bell Housing

- **Protection**: Keeps hydraulic components safe from external elements.

- **Vibration Dampening**: Reduces noise and vibration during operation, enhancing performance.

- **Heat Management**: Aids in dissipating heat generated during the hydraulic process, thus prolonging the life of the components.

Why Aluminum Alloys are a Smart Choice

Aluminum alloys have gained significant traction in the manufacturing of bell housings due to their unique properties. Let’s explore several reasons why choosing aluminum alloys is advantageous.

1. Lightweight Characteristics

One of the standout features of aluminum alloys is their **lightweight nature**. Compared to traditional materials like steel or cast iron, aluminum alloys can significantly reduce the overall weight of a hydraulic system. This weight reduction leads to:

- **Improved Efficiency**: Lighter components lead to lower energy consumption during operation.

- **Enhanced Mobility**: Ideal for applications requiring portability, such as mobile hydraulic machinery.

2. Exceptional Corrosion Resistance

Aluminum alloys exhibit outstanding resistance to corrosion, making them suitable for environments that may expose them to moisture and other corrosive agents. This attribute is particularly beneficial in:

- **Marine Applications**: Where exposure to saltwater can quickly deteriorate other materials.

- **Chemical Industries**: Where various chemicals can corrode traditional metals.

3. Superior Thermal Conductivity

The ability of aluminum alloys to conduct heat effectively enhances their suitability for bell housings. This characteristic facilitates:

- **Efficient Heat Dissipation**: Keeping hydraulic components cool and operational for longer periods.

- **Enhanced Performance**: Improved thermal management leads to better overall system efficiency.

4. Strength and Durability

Though lightweight, aluminum alloys do not compromise strength. Modern aluminum alloys can be engineered to achieve high tensile strength and durability, making them suitable for demanding applications. Key benefits include:

- **Longer Lifespan**: Reduced wear and tear in high-stress environments.

- **Resilience to Impact**: Capable of withstanding shocks and impacts without failing.

Types of Aluminum Alloys Used in Bell Housing

Understanding the specific types of aluminum alloys used in manufacturing bell housings can provide insight into their suitability for hydraulic systems. The most common aluminum alloys include:

1. 6061 Aluminum Alloy

6061 aluminum is a versatile alloy known for its excellent mechanical properties and weldability. Its characteristics include:

- **Good Corrosion Resistance**: Ensuring durability in various environments.

- **Easy to Fabricate**: Suitable for complex designs and shapes.

2. 7075 Aluminum Alloy

7075 aluminum is one of the strongest aluminum alloys available, often used in aerospace applications. Its main features are:

- **High Strength-to-Weight Ratio**: Ideal for heavy-duty applications.

- **Fatigue Resistance**: Suitable for applications that experience cyclic loading.

3. 5083 Aluminum Alloy

5083 aluminum is known for its high resistance to corrosion, especially in marine environments. This alloy boasts:

- **Excellent Weldability**: Ensuring structural integrity.

- **Good Strength**: Making it suitable for marine and industrial applications.

Applications of Aluminum Bell Housing in Hydraulic Systems

The utilization of aluminum alloys in hydraulic bell housings spans various industries. Here are some notable applications:

1. Automotive Industry

In automotive manufacturing, aluminum bell housings are increasingly favored due to their lightweight properties, contributing to better fuel efficiency without sacrificing strength.

2. Aerospace Industry

Aerospace applications demand materials that are both lightweight and strong. Aluminum alloys meet these standards, providing reliable performance in high-pressure environments.

3. Industrial Machinery

In industrial settings, hydraulic systems are vital for operations. Aluminum bell housings help in reducing the weight of machines, thereby increasing their efficiency and performance.

Cost Considerations of Aluminum Alloys

While aluminum alloys may have a higher initial cost compared to traditional materials, the long-term benefits often outweigh these expenses. Cost factors include:

- **Lower Maintenance Costs**: Due to corrosion resistance and durability.

- **Energy Savings**: Reduced energy consumption leads to lower operational costs over time.

Return on Investment (ROI)

Investing in aluminum bell housing may require a higher upfront investment, but when considering the **ROI**, it’s clear that the operational efficiencies and durability can lead to savings in maintenance and operational costs, ultimately making it a highly advantageous investment.

Choosing the Right Manufacturer for Aluminum Bell Housing

Selecting the right manufacturer for aluminum bell housings is essential to ensure quality and performance. Here are points to consider:

1. Experience and Reputation

Research potential manufacturers to evaluate their experience in producing aluminum components. Look for reviews and case studies to gauge their reputation in the industry.

2. Quality Assurance Processes

A manufacturer should have stringent quality control measures in place. This includes certifications for standards such as ISO 9001 to ensure products meet industry requirements.

3. Customization Capabilities

The ability to provide customized solutions can be a significant advantage. Manufacturers that offer design support can help businesses achieve optimal results tailored to specific applications.

Future Trends in Aluminum Alloys for Hydraulic Systems

As technology advances, the use of aluminum alloys in hydraulic systems is likely to evolve. Key trends to watch include:

1. Advanced Alloys and Treatments

With ongoing research, new aluminum alloys with enhanced properties may emerge, improving strength and corrosion resistance even further.

2. Increased Use of 3D Printing

The rise of **3D printing** technology in manufacturing aluminum components allows for more complex designs and reduced waste, making production more efficient.

3. Sustainability and Recycling

Aluminum is highly recyclable, and as industries move towards sustainability, the demand for recyclable materials like aluminum alloys will likely increase.

FAQs About Aluminum Alloys in Hydraulic Bell Housings

1. What are the main advantages of using aluminum alloys in hydraulic bell housings?

The primary advantages include lightweight characteristics, corrosion resistance, superior thermal conductivity, and strength.

2. How do aluminum alloys compare to steel in terms of performance?

Aluminum alloys provide similar strength but are significantly lighter, offering improved energy efficiency and reduced operational costs.

3. Are aluminum bell housings suitable for high-pressure applications?

Yes, certain aluminum alloys, particularly those engineered for strength like 7075, are suitable for high-pressure environments.

4. How does corrosion resistance affect the lifespan of bell housings?

Corrosion resistance prolongs the lifespan of bell housings by preventing degradation that can lead to failures in hydraulic systems.

5. Can aluminum bell housings be customized for specific applications?

Yes, many manufacturers offer customization options to meet the specific needs of various hydraulic systems.

Conclusion

In conclusion, aluminum alloys present a compelling choice for hydraulic system bell housings, offering an array of benefits such as weight savings, corrosion resistance, thermal conductivity, and durability. As industries continue to evolve towards more efficient and sustainable practices, the adoption of aluminum alloys is set to increase. By understanding the advantages and applications of aluminum alloys, engineers and manufacturers can make informed decisions that enhance performance and reliability in their hydraulic systems. Embracing these innovations today will pave the way for more efficient and effective hydraulic solutions in the future.

Keywords:

You Can Also Learn More About Industry Trends