Understanding Hydraulic Pump Bell Housing for Marine Applications

Release Time:

Jul 05,2025

Hydraulic pump bell housings are essential components in the marine industry, serving to protect hydraulic pumps and facilitate their efficient operation. These housings play a crucial role in ensuring that hydraulic pumps are securely mounted and properly aligned with the engine or power source. In marine applications, where exposure to harsh environments is common, the design and material select

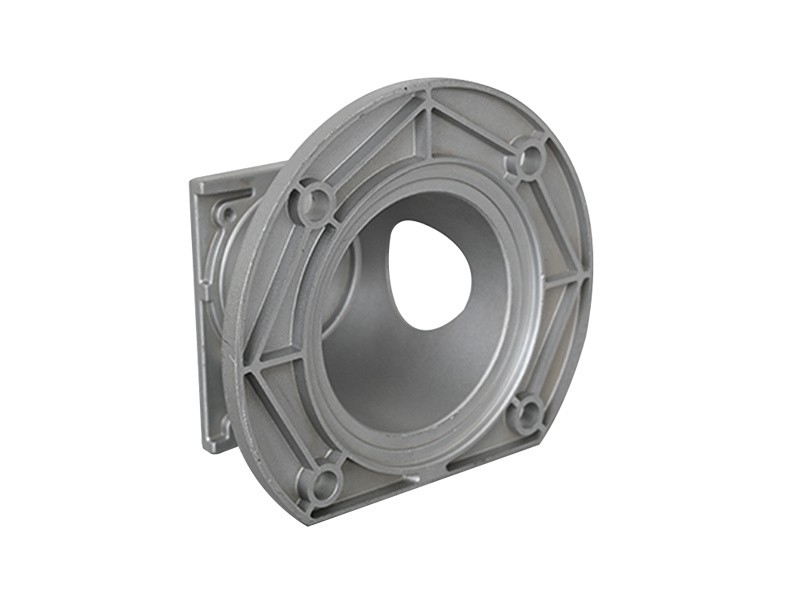

Hydraulic pump bell housings are essential components in the marine industry, serving to protect hydraulic pumps and facilitate their efficient operation. These housings play a crucial role in ensuring that hydraulic pumps are securely mounted and properly aligned with the engine or power source. In marine applications, where exposure to harsh environments is common, the design and material selection for bell housings are particularly important.

One of the primary functions of a hydraulic pump bell housing is to provide structural integrity. It supports the hydraulic pump while allowing for necessary movement and vibration without compromising the alignment. Proper alignment is critical, as misalignment can lead to increased wear and tear on the hydraulic pump, reducing its operational efficiency and lifespan.

In marine environments, bell housings are often constructed from materials that resist corrosion and withstand extreme conditions. Stainless steel and aluminum are popular choices due to their durability and resistance to marine corrosion. Manufacturers may also incorporate coatings or finishes to enhance corrosion resistance further, ensuring that the bell housing can withstand the saltwater environment commonly found in marine applications.

Another vital aspect of hydraulic pump bell housings is their design, which may vary based on the specific requirements of the marine application. For instance, some designs may incorporate ventilation features to help dissipate heat generated during operation, while others may include access points for maintenance and inspection purposes. It is crucial for professionals selecting a bell housing to consider the specific operational parameters of their hydraulic systems to ensure optimal performance.

Moreover, hydraulic pump bell housings can impact the overall efficiency of hydraulic systems. A well-designed bell housing allows for better fluid flow and minimizes pressure drops, which can improve the responsiveness of hydraulic systems in marine applications. This efficiency is particularly important in demanding situations, such as when operating heavy machinery or navigating challenging waters.

Finally, when discussing hydraulic pump bell housings, it is essential to recognize the importance of proper installation and maintenance. Ensuring that the bell housing is correctly installed and regularly inspected can prevent potential issues, such as leaks or misalignment, which can lead to costly repairs and downtime.

In summary, hydraulic pump bell housings are critical components in the marine industry, providing support, protection, and efficiency to hydraulic systems. Understanding their design, materials, and maintenance requirements is essential for professionals looking to optimize their marine hydraulic applications. By focusing on these factors, businesses can enhance reliability and performance, ultimately leading to improved operational success in marine environments.

One of the primary functions of a hydraulic pump bell housing is to provide structural integrity. It supports the hydraulic pump while allowing for necessary movement and vibration without compromising the alignment. Proper alignment is critical, as misalignment can lead to increased wear and tear on the hydraulic pump, reducing its operational efficiency and lifespan.

In marine environments, bell housings are often constructed from materials that resist corrosion and withstand extreme conditions. Stainless steel and aluminum are popular choices due to their durability and resistance to marine corrosion. Manufacturers may also incorporate coatings or finishes to enhance corrosion resistance further, ensuring that the bell housing can withstand the saltwater environment commonly found in marine applications.

Another vital aspect of hydraulic pump bell housings is their design, which may vary based on the specific requirements of the marine application. For instance, some designs may incorporate ventilation features to help dissipate heat generated during operation, while others may include access points for maintenance and inspection purposes. It is crucial for professionals selecting a bell housing to consider the specific operational parameters of their hydraulic systems to ensure optimal performance.

Moreover, hydraulic pump bell housings can impact the overall efficiency of hydraulic systems. A well-designed bell housing allows for better fluid flow and minimizes pressure drops, which can improve the responsiveness of hydraulic systems in marine applications. This efficiency is particularly important in demanding situations, such as when operating heavy machinery or navigating challenging waters.

Finally, when discussing hydraulic pump bell housings, it is essential to recognize the importance of proper installation and maintenance. Ensuring that the bell housing is correctly installed and regularly inspected can prevent potential issues, such as leaks or misalignment, which can lead to costly repairs and downtime.

In summary, hydraulic pump bell housings are critical components in the marine industry, providing support, protection, and efficiency to hydraulic systems. Understanding their design, materials, and maintenance requirements is essential for professionals looking to optimize their marine hydraulic applications. By focusing on these factors, businesses can enhance reliability and performance, ultimately leading to improved operational success in marine environments.

Keywords:

You Can Also Learn More About Industry Trends