Understanding Hydraulic Pump Bell Housings for Mining Equipment

Release Time:

Jul 07,2025

Hydraulic pump bell housings are essential components in the realm of mining equipment, serving as protective structures that enclose hydraulic pumps. These housings are designed not only to secure the pump but also to provide stability, alignment, and efficient operation under various environmental conditions commonly encountered in mining operations. One of the primary functions of a hydraulic p

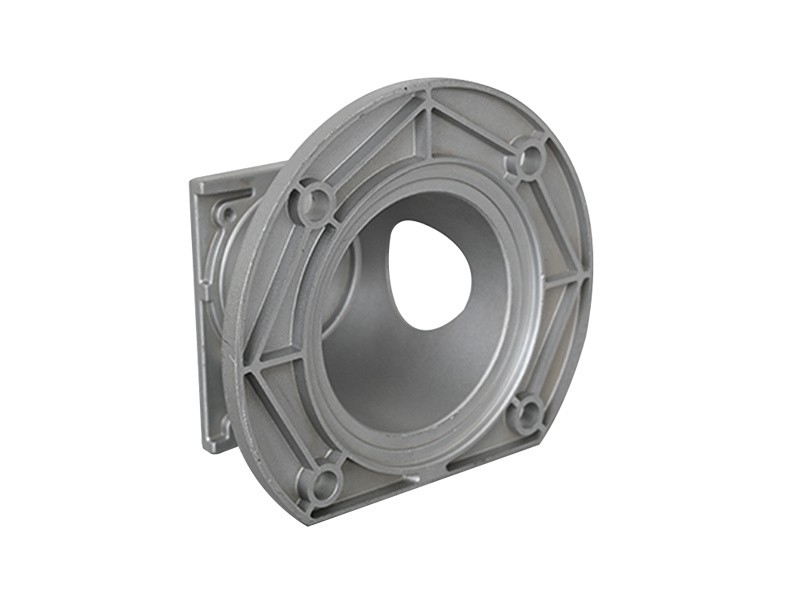

Hydraulic pump bell housings are essential components in the realm of mining equipment, serving as protective structures that enclose hydraulic pumps. These housings are designed not only to secure the pump but also to provide stability, alignment, and efficient operation under various environmental conditions commonly encountered in mining operations.

One of the primary functions of a hydraulic pump bell housing is to facilitate the connection between the hydraulic pump and the power source, usually an engine or motor. This connection is crucial because it ensures that the pump receives the necessary power to operate effectively. In mining applications, where machinery often operates in rugged terrains and harsh environments, the integrity of the bell housing is vital. It must be robust enough to withstand vibrations, shocks, and potential impacts from the surrounding environment.

The design of hydraulic pump bell housings can vary based on the specific requirements of mining equipment. Engineers typically consider factors such as material selection, weight distribution, and thermal management when designing these housings. Common materials include high-strength alloys that can endure corrosion and wear, which are prevalent in mining environments due to the exposure to moisture, dust, and abrasive materials.

Moreover, proper venting and drainage within the bell housing are essential to prevent the accumulation of fluids or debris that could hinder the performance of the hydraulic pump. Ensuring that these housings are designed with adequate drainage channels can significantly prolong the life of the hydraulic components and reduce maintenance needs.

In addition to functional aspects, the installation of hydraulic pump bell housings requires precision. Misalignment during installation can lead to premature wear and tear, reduced efficiency, and even catastrophic failures. Therefore, thorough alignment checks and proper installation practices are crucial for optimal performance.

Regular maintenance and inspection of hydraulic pump bell housings are also necessary to ensure their longevity and functionality. Industry professionals recommend routine checks for signs of wear, corrosion, or damage. Addressing these issues promptly can prevent costly downtime and enhance the overall efficiency of mining operations.

In conclusion, hydraulic pump bell housings play a pivotal role in the performance and reliability of mining equipment. By understanding their importance, design considerations, and maintenance requirements, industry professionals can ensure that their hydraulic systems operate at peak efficiency, even in the most challenging conditions. The integration of high-quality bell housings into hydraulic systems is a key factor in achieving operational success in the mining sector.

One of the primary functions of a hydraulic pump bell housing is to facilitate the connection between the hydraulic pump and the power source, usually an engine or motor. This connection is crucial because it ensures that the pump receives the necessary power to operate effectively. In mining applications, where machinery often operates in rugged terrains and harsh environments, the integrity of the bell housing is vital. It must be robust enough to withstand vibrations, shocks, and potential impacts from the surrounding environment.

The design of hydraulic pump bell housings can vary based on the specific requirements of mining equipment. Engineers typically consider factors such as material selection, weight distribution, and thermal management when designing these housings. Common materials include high-strength alloys that can endure corrosion and wear, which are prevalent in mining environments due to the exposure to moisture, dust, and abrasive materials.

Moreover, proper venting and drainage within the bell housing are essential to prevent the accumulation of fluids or debris that could hinder the performance of the hydraulic pump. Ensuring that these housings are designed with adequate drainage channels can significantly prolong the life of the hydraulic components and reduce maintenance needs.

In addition to functional aspects, the installation of hydraulic pump bell housings requires precision. Misalignment during installation can lead to premature wear and tear, reduced efficiency, and even catastrophic failures. Therefore, thorough alignment checks and proper installation practices are crucial for optimal performance.

Regular maintenance and inspection of hydraulic pump bell housings are also necessary to ensure their longevity and functionality. Industry professionals recommend routine checks for signs of wear, corrosion, or damage. Addressing these issues promptly can prevent costly downtime and enhance the overall efficiency of mining operations.

In conclusion, hydraulic pump bell housings play a pivotal role in the performance and reliability of mining equipment. By understanding their importance, design considerations, and maintenance requirements, industry professionals can ensure that their hydraulic systems operate at peak efficiency, even in the most challenging conditions. The integration of high-quality bell housings into hydraulic systems is a key factor in achieving operational success in the mining sector.

Keywords:

You Can Also Learn More About Industry Trends