Essential Insights on Hydraulic Pump Bell Housing for Marine Applications

Release Time:

Aug 04,2025

In marine applications, hydraulic pumps are crucial for operating various systems, from steering mechanisms to winches and deck machinery. One critical component that ensures the efficient operation of these hydraulic pumps is the bell housing. The hydraulic pump bell housing serves as a protective enclosure that supports the pump and connects it to the engine or power source. Understanding its de

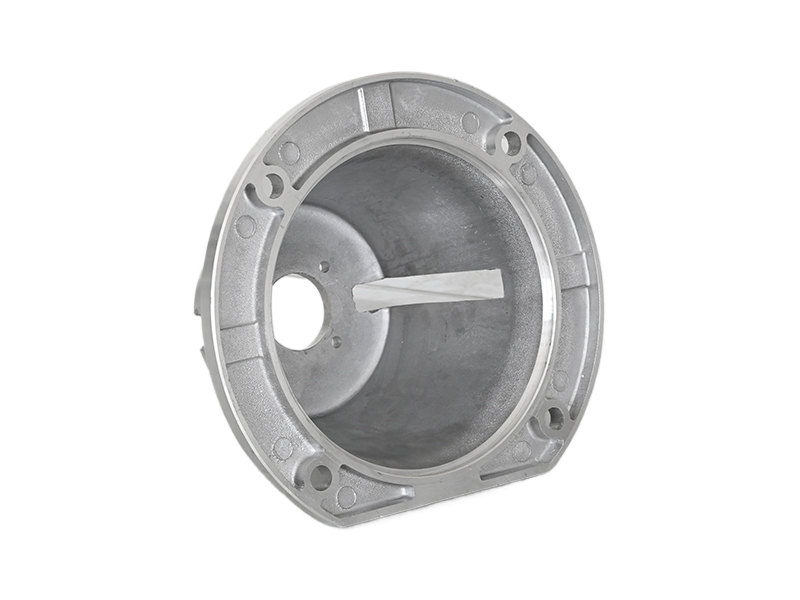

In marine applications, hydraulic pumps are crucial for operating various systems, from steering mechanisms to winches and deck machinery. One critical component that ensures the efficient operation of these hydraulic pumps is the bell housing. The hydraulic pump bell housing serves as a protective enclosure that supports the pump and connects it to the engine or power source. Understanding its design and functionality can significantly impact the performance and longevity of hydraulic systems in marine settings.

The bell housing is typically constructed from durable materials that can withstand harsh marine environments, including saltwater exposure and extreme temperatures. This resilience is essential for maintaining the integrity of the hydraulic pump, as any failure in this area could lead to significant operational problems. It is also designed to minimize vibration and noise, ensuring smoother operation during use.

Proper alignment and installation of the hydraulic pump bell housing are critical. Misalignment can lead to premature wear and tear on the hydraulic pump components, reducing efficiency and increasing maintenance costs. It's vital for marine operators to ensure that the bell housing is correctly positioned and secured during installation to prevent such issues.

In addition to structural support, the hydraulic pump bell housing also plays a vital role in the hydraulic fluid flow. It must be designed to facilitate optimal fluid passage while preventing leaks. Any leakages in the hydraulic system can lead to decreased performance and potential damage to the marine equipment. Therefore, ensuring the bell housing is sealed correctly and constructed from appropriate materials is vital for operational efficiency.

Regular inspection and maintenance of the hydraulic pump bell housing are also recommended. Operators should check for signs of wear, corrosion, or damage. Early detection of issues can prevent more significant problems down the line, ensuring that the hydraulic system operates efficiently and reliably.

When considering the hydraulic pump bell housing for marine applications, it’s essential to understand the specific requirements of your hydraulic system. Factors such as the type of hydraulic fluid, the operating conditions, and the intended application will all influence the design and construction of the bell housing. Custom solutions may be necessary to meet unique operational demands, ensuring optimal performance in marine environments.

In conclusion, the hydraulic pump bell housing is a critical component that should not be overlooked in marine applications. Its design, material selection, and proper installation play significant roles in the overall efficiency and reliability of hydraulic systems. By investing time and resources into understanding and maintaining this component, marine operators can achieve higher performance and longevity for their hydraulic systems.

The bell housing is typically constructed from durable materials that can withstand harsh marine environments, including saltwater exposure and extreme temperatures. This resilience is essential for maintaining the integrity of the hydraulic pump, as any failure in this area could lead to significant operational problems. It is also designed to minimize vibration and noise, ensuring smoother operation during use.

Proper alignment and installation of the hydraulic pump bell housing are critical. Misalignment can lead to premature wear and tear on the hydraulic pump components, reducing efficiency and increasing maintenance costs. It's vital for marine operators to ensure that the bell housing is correctly positioned and secured during installation to prevent such issues.

In addition to structural support, the hydraulic pump bell housing also plays a vital role in the hydraulic fluid flow. It must be designed to facilitate optimal fluid passage while preventing leaks. Any leakages in the hydraulic system can lead to decreased performance and potential damage to the marine equipment. Therefore, ensuring the bell housing is sealed correctly and constructed from appropriate materials is vital for operational efficiency.

Regular inspection and maintenance of the hydraulic pump bell housing are also recommended. Operators should check for signs of wear, corrosion, or damage. Early detection of issues can prevent more significant problems down the line, ensuring that the hydraulic system operates efficiently and reliably.

When considering the hydraulic pump bell housing for marine applications, it’s essential to understand the specific requirements of your hydraulic system. Factors such as the type of hydraulic fluid, the operating conditions, and the intended application will all influence the design and construction of the bell housing. Custom solutions may be necessary to meet unique operational demands, ensuring optimal performance in marine environments.

In conclusion, the hydraulic pump bell housing is a critical component that should not be overlooked in marine applications. Its design, material selection, and proper installation play significant roles in the overall efficiency and reliability of hydraulic systems. By investing time and resources into understanding and maintaining this component, marine operators can achieve higher performance and longevity for their hydraulic systems.

Keywords:

You Can Also Learn More About Industry Trends