Understanding Hydraulic Oil Tank Manhole Covers with Bolts: Key Insights

Release Time:

Aug 06,2025

Hydraulic oil tank manhole covers with bolts are crucial components in the automotive engine system, particularly concerning hydraulic systems. These covers serve as access points for maintenance and inspection of hydraulic tanks, ensuring that the system remains functional and safe. By providing a sealed environment, they prevent contamination and loss of hydraulic fluid, which is vital for the e

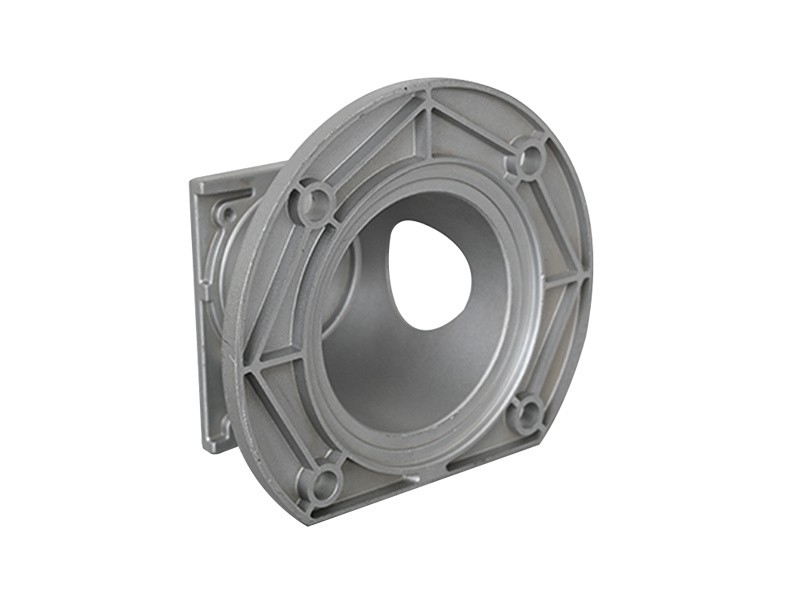

Hydraulic oil tank manhole covers with bolts are crucial components in the automotive engine system, particularly concerning hydraulic systems. These covers serve as access points for maintenance and inspection of hydraulic tanks, ensuring that the system remains functional and safe. By providing a sealed environment, they prevent contamination and loss of hydraulic fluid, which is vital for the efficient operation of hydraulic machinery.

When considering hydraulic oil tank manhole covers, it’s important to recognize the role of bolts in securing the cover. Bolts are essential fasteners that provide the necessary strength to withstand pressure and prevent leaks. The design and material of these bolts can significantly affect the durability and effectiveness of the manhole cover. Typically, high-strength steel or corrosion-resistant materials are preferred to enhance longevity and reliability in various operating conditions.

The size and design of the manhole cover are also critical factors. A well-designed cover will allow for easy access while being robust enough to endure the stresses of hydraulic operations. It should also accommodate the specific dimensions of the hydraulic tank, ensuring a proper fit. Additionally, the sealing mechanism—often a gasket or O-ring—plays a significant role in maintaining a leak-proof environment. Choosing the right sealing material can prevent fluid loss due to wear or environmental factors.

Another consideration is the maintenance of these covers. Regular inspections are vital to ensure that the bolts are secure and that the seals are intact. Over time, exposure to hydraulic fluids and varying temperatures can affect the integrity of the cover and seals, necessitating periodic checks. Proper maintenance can extend the life of the hydraulic system, preventing costly repairs and downtime.

Furthermore, when installing or replacing a manhole cover, it’s crucial to follow the manufacturer’s guidelines for torque specifications. Over-tightening bolts can lead to deformation of the cover, while under-tightening can result in leaks. It’s advisable to use a torque wrench to ensure that the bolts are fastened to the appropriate specifications.

In conclusion, hydraulic oil tank manhole covers with bolts are essential for the safe and efficient operation of hydraulic systems in automotive engines. Understanding their design, materials, and maintenance requirements can help ensure that these components function effectively, supporting the overall performance of the engine system. By paying close attention to the installation and upkeep of these covers, you can maintain the integrity of your hydraulic systems and avoid potential issues down the line.

When considering hydraulic oil tank manhole covers, it’s important to recognize the role of bolts in securing the cover. Bolts are essential fasteners that provide the necessary strength to withstand pressure and prevent leaks. The design and material of these bolts can significantly affect the durability and effectiveness of the manhole cover. Typically, high-strength steel or corrosion-resistant materials are preferred to enhance longevity and reliability in various operating conditions.

The size and design of the manhole cover are also critical factors. A well-designed cover will allow for easy access while being robust enough to endure the stresses of hydraulic operations. It should also accommodate the specific dimensions of the hydraulic tank, ensuring a proper fit. Additionally, the sealing mechanism—often a gasket or O-ring—plays a significant role in maintaining a leak-proof environment. Choosing the right sealing material can prevent fluid loss due to wear or environmental factors.

Another consideration is the maintenance of these covers. Regular inspections are vital to ensure that the bolts are secure and that the seals are intact. Over time, exposure to hydraulic fluids and varying temperatures can affect the integrity of the cover and seals, necessitating periodic checks. Proper maintenance can extend the life of the hydraulic system, preventing costly repairs and downtime.

Furthermore, when installing or replacing a manhole cover, it’s crucial to follow the manufacturer’s guidelines for torque specifications. Over-tightening bolts can lead to deformation of the cover, while under-tightening can result in leaks. It’s advisable to use a torque wrench to ensure that the bolts are fastened to the appropriate specifications.

In conclusion, hydraulic oil tank manhole covers with bolts are essential for the safe and efficient operation of hydraulic systems in automotive engines. Understanding their design, materials, and maintenance requirements can help ensure that these components function effectively, supporting the overall performance of the engine system. By paying close attention to the installation and upkeep of these covers, you can maintain the integrity of your hydraulic systems and avoid potential issues down the line.

Keywords:

You Can Also Learn More About Industry Trends