Understanding Hydraulic Pump Bell Housings for Marine Applications

Release Time:

Jul 25,2025

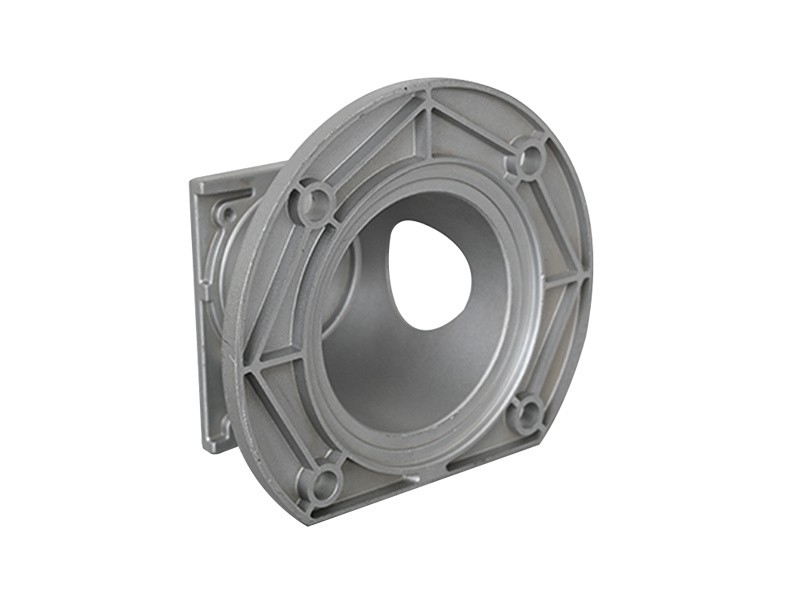

Hydraulic pump bell housings are crucial components in marine applications, where they serve to protect and support hydraulic pumps while ensuring efficient operation in demanding environments. The bell housing acts as a casing around the hydraulic pump, providing a secure and stable connection to the engine or other driving mechanisms, which is particularly vital in marine settings due to the con

Hydraulic pump bell housings are crucial components in marine applications, where they serve to protect and support hydraulic pumps while ensuring efficient operation in demanding environments. The bell housing acts as a casing around the hydraulic pump, providing a secure and stable connection to the engine or other driving mechanisms, which is particularly vital in marine settings due to the constant movement and vibrations associated with watercraft.

When considering hydraulic pump bell housings for marine applications, several design factors come into play. First and foremost, the material selection is critical. Marine environments are harsh, characterized by exposure to saltwater, humidity, and varying temperatures. Therefore, utilizing corrosion-resistant materials, such as stainless steel or specially coated aluminum, is essential to ensure the longevity and reliability of the housing.

Another key aspect is the size and shape of the bell housing, which must be compatible with the specific hydraulic pump model and the marine vessel’s layout. Proper alignment of the hydraulic pump within the bell housing is necessary to avoid undue stress on the components, which can lead to premature failure. Additionally, the design should facilitate adequate ventilation and cooling to prevent overheating during operation, further enhancing efficiency and performance.

In marine applications, the hydraulic pump bell housing also plays a role in noise reduction. By providing a more enclosed space around the pump, it can help dampen sound, which is crucial for passenger comfort and adherence to maritime regulations concerning noise levels.

Maintenance is another critical consideration. Regular inspection and maintenance of the hydraulic pump bell housing can prevent issues before they escalate. Key practices include checking for signs of wear or corrosion, ensuring proper seals and gaskets are intact, and confirming that the housing remains securely attached to the hydraulic pump and the engine. Implementing a routine maintenance schedule can significantly extend the lifespan of the hydraulic system and enhance overall operational safety.

In summary, hydraulic pump bell housings are vital components in marine applications, requiring careful consideration of materials, design, and maintenance practices. Understanding these aspects can lead to better performance and reliability in maritime hydraulic systems, ultimately benefiting operators and enhancing safety at sea. Whether you're involved in the design, installation, or maintenance of these systems, a solid grasp of hydraulic pump bell housings will empower you to make informed decisions that contribute to the success of marine operations.

When considering hydraulic pump bell housings for marine applications, several design factors come into play. First and foremost, the material selection is critical. Marine environments are harsh, characterized by exposure to saltwater, humidity, and varying temperatures. Therefore, utilizing corrosion-resistant materials, such as stainless steel or specially coated aluminum, is essential to ensure the longevity and reliability of the housing.

Another key aspect is the size and shape of the bell housing, which must be compatible with the specific hydraulic pump model and the marine vessel’s layout. Proper alignment of the hydraulic pump within the bell housing is necessary to avoid undue stress on the components, which can lead to premature failure. Additionally, the design should facilitate adequate ventilation and cooling to prevent overheating during operation, further enhancing efficiency and performance.

In marine applications, the hydraulic pump bell housing also plays a role in noise reduction. By providing a more enclosed space around the pump, it can help dampen sound, which is crucial for passenger comfort and adherence to maritime regulations concerning noise levels.

Maintenance is another critical consideration. Regular inspection and maintenance of the hydraulic pump bell housing can prevent issues before they escalate. Key practices include checking for signs of wear or corrosion, ensuring proper seals and gaskets are intact, and confirming that the housing remains securely attached to the hydraulic pump and the engine. Implementing a routine maintenance schedule can significantly extend the lifespan of the hydraulic system and enhance overall operational safety.

In summary, hydraulic pump bell housings are vital components in marine applications, requiring careful consideration of materials, design, and maintenance practices. Understanding these aspects can lead to better performance and reliability in maritime hydraulic systems, ultimately benefiting operators and enhancing safety at sea. Whether you're involved in the design, installation, or maintenance of these systems, a solid grasp of hydraulic pump bell housings will empower you to make informed decisions that contribute to the success of marine operations.

Keywords:

You Can Also Learn More About Industry Trends