Understanding Hydraulic Pump Bell Housing for Mining Equipment: Key Insights and Practical Knowledge

Release Time:

Jul 27,2025

Hydraulic pump bell housing is a critical component in mining equipment, playing a vital role in the overall functionality and durability of hydraulic systems. In the mining industry, where machinery operates under harsh conditions, understanding the significance of this component can greatly enhance operational efficiency and equipment longevity. The bell housing serves as a protective casing for

Hydraulic pump bell housing is a critical component in mining equipment, playing a vital role in the overall functionality and durability of hydraulic systems. In the mining industry, where machinery operates under harsh conditions, understanding the significance of this component can greatly enhance operational efficiency and equipment longevity.

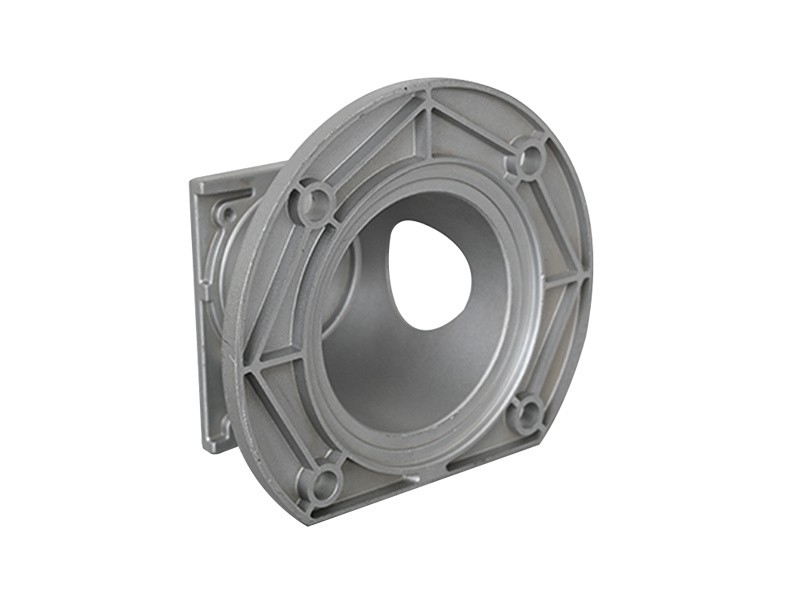

The bell housing serves as a protective casing for the hydraulic pump, safeguarding it from external contaminants such as dust, dirt, and moisture that are prevalent in mining environments. This protection is essential as it prevents damage to internal components and ensures that the hydraulic fluid remains uncontaminated, which is crucial for maintaining the performance of hydraulic systems.

When selecting a hydraulic pump bell housing for mining equipment, several design considerations should be taken into account. First, the material used in the construction of the bell housing must be robust enough to withstand the rigors of mining operations. Common materials include high-strength steel or aluminum alloys, which offer both durability and resistance to corrosion. Additionally, the housing design should facilitate efficient heat dissipation, as hydraulic pumps can generate significant heat during operation.

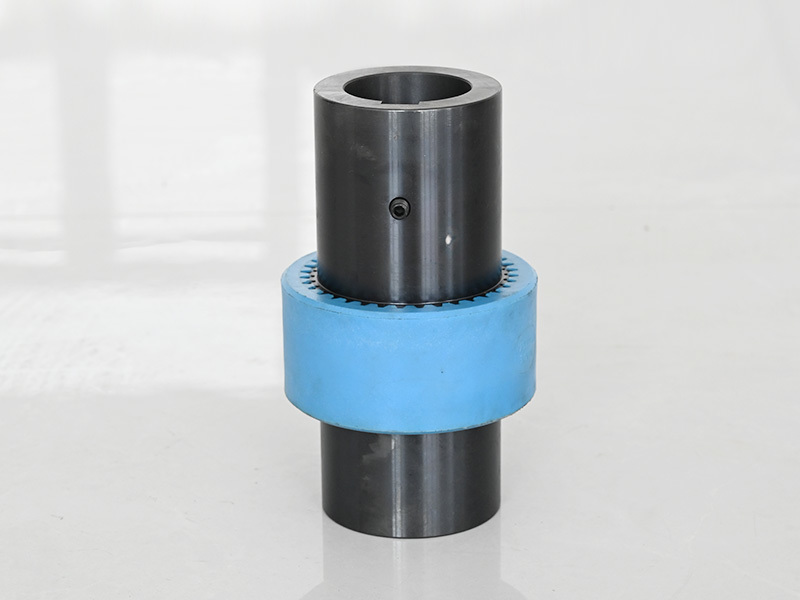

Another important factor to consider is the alignment and mounting of the bell housing. Proper alignment is essential to ensure that the hydraulic pump operates smoothly and efficiently. Misalignment can lead to excessive wear and tear on the pump and associated components, ultimately resulting in costly downtime. Therefore, it is advisable to consult with engineering professionals during the installation process to guarantee optimal alignment.

Maintenance is key to prolonging the life of hydraulic pump bell housing and the machinery it protects. Regular inspections should be conducted to check for any signs of wear, corrosion, or damage. Keeping the bell housing clean and free from debris will help maintain the integrity of the hydraulic system. Additionally, it is important to monitor the hydraulic fluid for contamination, as this can significantly affect the performance and reliability of the entire system.

In conclusion, understanding the role of hydraulic pump bell housing in mining equipment is essential for professionals in the industry. By considering material selection, design features, and maintenance practices, operators can enhance the performance and lifespan of their hydraulic systems. Investing time and resources in these areas will ultimately lead to greater efficiency and productivity in mining operations, ensuring that equipment remains reliable in challenging environments.

The bell housing serves as a protective casing for the hydraulic pump, safeguarding it from external contaminants such as dust, dirt, and moisture that are prevalent in mining environments. This protection is essential as it prevents damage to internal components and ensures that the hydraulic fluid remains uncontaminated, which is crucial for maintaining the performance of hydraulic systems.

When selecting a hydraulic pump bell housing for mining equipment, several design considerations should be taken into account. First, the material used in the construction of the bell housing must be robust enough to withstand the rigors of mining operations. Common materials include high-strength steel or aluminum alloys, which offer both durability and resistance to corrosion. Additionally, the housing design should facilitate efficient heat dissipation, as hydraulic pumps can generate significant heat during operation.

Another important factor to consider is the alignment and mounting of the bell housing. Proper alignment is essential to ensure that the hydraulic pump operates smoothly and efficiently. Misalignment can lead to excessive wear and tear on the pump and associated components, ultimately resulting in costly downtime. Therefore, it is advisable to consult with engineering professionals during the installation process to guarantee optimal alignment.

Maintenance is key to prolonging the life of hydraulic pump bell housing and the machinery it protects. Regular inspections should be conducted to check for any signs of wear, corrosion, or damage. Keeping the bell housing clean and free from debris will help maintain the integrity of the hydraulic system. Additionally, it is important to monitor the hydraulic fluid for contamination, as this can significantly affect the performance and reliability of the entire system.

In conclusion, understanding the role of hydraulic pump bell housing in mining equipment is essential for professionals in the industry. By considering material selection, design features, and maintenance practices, operators can enhance the performance and lifespan of their hydraulic systems. Investing time and resources in these areas will ultimately lead to greater efficiency and productivity in mining operations, ensuring that equipment remains reliable in challenging environments.

Keywords:

You Can Also Learn More About Industry Trends