A Comprehensive Guide to KTR Coupling Types: Applications and Advantages

Release Time:

Jul 26,2025

A Comprehensive Guide to KTR Coupling Types: Applications and Advantages Table of Contents 1. Introduction to KTR Couplings 2. What are KTR Couplings? 3. Types of KTR Couplings 3.1 Flexible Couplings 3.2 Rigid Couplings 3.3 Safety Couplings 3.4 Torque Limiting Couplings 4. Applications of KTR Couplings 5. Advantages of Using KT

A Comprehensive Guide to KTR Coupling Types: Applications and Advantages

Table of Contents

- 1. Introduction to KTR Couplings

- 2. What are KTR Couplings?

- 3. Types of KTR Couplings

- 4. Applications of KTR Couplings

- 5. Advantages of Using KTR Couplings

- 6. How to Select the Right KTR Coupling

- 7. Maintenance and Care for KTR Couplings

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to KTR Couplings

KTR couplings are essential components in various industrial applications, enhancing the efficiency and reliability of machinery. These couplings connect different parts of machines, allowing them to transmit torque while compensating for misalignments. With the increasing demand for high-performance industrial equipment, understanding the types and applications of KTR couplings becomes critical for engineers and technicians alike.

2. What are KTR Couplings?

KTR couplings are mechanical devices designed to transmit rotational motion and torque between two shafts. They serve multiple purposes, including damping vibrations, compensating for axial and angular misalignments, and protecting equipment from overload situations. KTR, a renowned manufacturer, offers a wide range of coupling solutions tailored to meet specific industrial needs.

3. Types of KTR Couplings

KTR couplings are categorized based on their design and functionality. Below we delve into the primary types of KTR couplings, highlighting their unique characteristics.

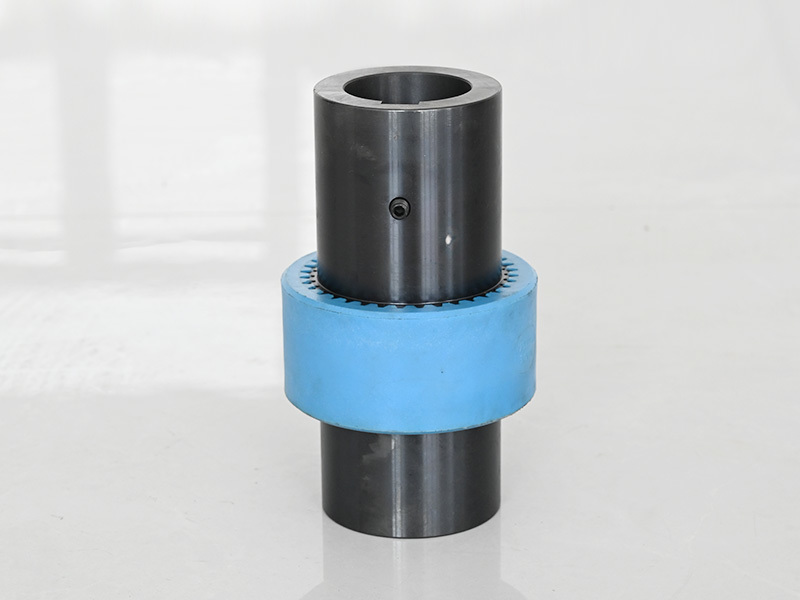

3.1 Flexible Couplings

Flexible couplings are designed to accommodate misalignments between shafts. These couplings utilize elastic elements that allow for flexibility while maintaining a secure connection. They are ideal for applications where precise alignment is challenging, such as in robotics and conveyor systems.

3.2 Rigid Couplings

Rigid couplings connect two shafts without any play, ensuring precise transmission of torque. These couplings are typically used in applications where the shafts are perfectly aligned. Industries such as manufacturing frequently employ rigid couplings for machinery that requires high torque transmission.

3.3 Safety Couplings

Safety couplings are designed to disconnect in case of overload conditions, protecting the connected machinery. These couplings are vital in applications where sudden torque spikes can lead to damage, such as in gearboxes and motor drives. By preventing damage, safety couplings enhance the longevity of equipment.

3.4 Torque Limiting Couplings

Torque limiting couplings protect machinery from excessive torque by slipping when a predetermined limit is reached. This feature is critical in applications involving heavy machinery, ensuring that motors and gears are not subjected to damaging forces. Torque limiting couplings are widely used in construction and agricultural equipment.

4. Applications of KTR Couplings

KTR couplings find applications across various industries, owing to their versatility and reliability. Below are some of the key sectors where these couplings excel:

4.1 Manufacturing Industry

In the manufacturing sector, KTR couplings play a crucial role in driving machinery such as conveyor belts, mixers, and packaging machines. Their ability to handle misalignment and vibration makes them indispensable in production lines.

4.2 Robotics

Robotic systems require precise movement and coordination, which KTR flexible couplings provide. These couplings facilitate smooth operations while accommodating the dynamics of robot movements, ensuring accuracy in tasks such as assembly and welding.

4.3 Automotive Sector

The automotive industry uses KTR couplings in various applications, including electric and hybrid vehicles. Their ability to handle torque fluctuations is critical for reliable performance in automotive drivetrains.

4.4 Agriculture and Construction

Agricultural and construction machinery often operates under harsh conditions, making robust coupling solutions like KTR essential. Torque limiting couplings ensure that heavy equipment operates safely, preventing breakdowns during demanding tasks.

5. Advantages of Using KTR Couplings

Choosing KTR couplings offers several benefits that enhance machine performance and longevity.

5.1 Enhanced Durability

KTR couplings are engineered to withstand extreme conditions, ensuring long service life even in challenging environments. Their robust design reduces the likelihood of premature wear and tear.

5.2 Flexibility and Compensation

The flexible design of KTR couplings allows for compensation of misalignments, which is essential for maintaining operational efficiency. This flexibility reduces stress on connected machinery, leading to fewer breakdowns.

5.3 Safety Features

With built-in safety mechanisms, KTR couplings offer enhanced protection for machinery. Safety couplings reduce the risk of damage during overload situations, safeguarding both equipment and operators.

5.4 Easy Installation and Maintenance

KTR couplings are designed for straightforward installation, minimizing downtime during setup. Their maintenance-friendly features ensure that regular checks can be conducted easily, promoting optimal performance.

6. How to Select the Right KTR Coupling

Selecting the appropriate KTR coupling involves several considerations to ensure optimal performance.

6.1 Determine Torque Requirements

Understanding the torque requirements of your application is crucial. This ensures that the selected coupling can handle the necessary load without failure.

6.2 Assess Misalignment Needs

Evaluate the level of misalignment expected in your application. Flexible couplings are ideal for applications with significant misalignment, while rigid couplings suit perfectly aligned shafts.

6.3 Consider Operating Environment

The operating environment plays a significant role in coupling selection. Consider factors such as temperature, humidity, and exposure to chemicals when choosing a KTR coupling.

6.4 Review Safety and Performance Features

Ensure the selected coupling includes necessary safety features, particularly if the application involves high torque or heavy loads. Torque limiting couplings are essential for applications prone to overload situations.

7. Maintenance and Care for KTR Couplings

Proper maintenance is key to ensuring the longevity and reliability of KTR couplings.

7.1 Regular Inspections

Conduct regular inspections to check for signs of wear, misalignment, or damage. Early detection of issues can prevent unexpected breakdowns.

7.2 Lubrication

Follow the manufacturer's recommendations for lubrication to reduce friction and wear. Proper lubrication extends the life of the coupling and ensures smooth operation.

7.3 Cleaning

Keep the couplings clean and free from debris. Accumulated dirt can lead to misalignment and increased wear, negatively impacting performance.

8. Frequently Asked Questions

8.1 What is the main purpose of KTR couplings?

KTR couplings primarily connect shafts in machinery, transmitting torque while accommodating misalignments.

8.2 How do I know which KTR coupling is right for my application?

Consider factors like torque requirements, misalignment, operating environment, and necessary safety features to select the appropriate coupling.

8.3 Are KTR couplings easy to install?

Yes, KTR couplings are designed for straightforward installation, minimizing downtime during setup.

8.4 How often should KTR couplings be serviced?

Regular inspections should be conducted, with maintenance schedules tailored to the application and operating conditions.

8.5 Can KTR couplings handle high torque applications?

Yes, KTR offers couplings specifically designed for high torque applications, including safety and torque limiting features.

9. Conclusion

KTR couplings are integral to the efficiency and reliability of a wide range of industrial applications. Understanding the various types of KTR couplings, their applications, and advantages can significantly impact machine performance. By selecting the right coupling for your specific needs and maintaining it properly, you can ensure optimal operation while maximizing the lifespan of your equipment. Emphasizing quality and performance, KTR couplings provide the reliability that modern industries demand.

Keywords:

You Can Also Learn More About Industry Trends