The Connection Between Hydraulic Pump Bell Housing and Engine Efficiency

Release Time:

Feb 10,2026

The Connection Between Hydraulic Pump Bell Housing and Engine Efficiency Table of Contents 1. Introduction 2. Understanding Hydraulic Pump Bell Housing 2.1 What is a Hydraulic Pump Bell Housing? 2.2 The Role of Bell Housing in Hydraulic Systems 3. Engine Efficiency: What Does It Mean? 3.1 Defining Engine Efficiency 3.2 Factors Influencing Engine Efficiency 4. The Relationship Between Hydraulic Pum

The Connection Between Hydraulic Pump Bell Housing and Engine Efficiency

Table of Contents

1. Introduction

2. Understanding Hydraulic Pump Bell Housing

2.1 What is a Hydraulic Pump Bell Housing?

2.2 The Role of Bell Housing in Hydraulic Systems

3. Engine Efficiency: What Does It Mean?

3.1 Defining Engine Efficiency

3.2 Factors Influencing Engine Efficiency

4. The Relationship Between Hydraulic Pump Bell Housing and Engine Performance

4.1 How Bell Housing Affects Hydraulic Pump Functionality

4.2 The Impact on Engine Output and Fuel Efficiency

5. Maintenance Tips for Hydraulic Pump Bell Housing

5.1 Regular Inspections

5.2 Common Issues and Solutions

6. Upgrades and Innovations in Hydraulic Systems

6.1 Modern Materials and Technologies

6.2 The Future of Hydraulic Pump Bell Housing

7. Conclusion

8. Frequently Asked Questions (FAQs)

1. Introduction

In the automotive industry, the efficiency of an engine is paramount. One often overlooked component that significantly contributes to engine efficiency is the **hydraulic pump bell housing**. This article delves into the connection between the hydraulic pump bell housing and engine efficiency, shedding light on how this component can influence overall vehicle performance.

2. Understanding Hydraulic Pump Bell Housing

2.1 What is a Hydraulic Pump Bell Housing?

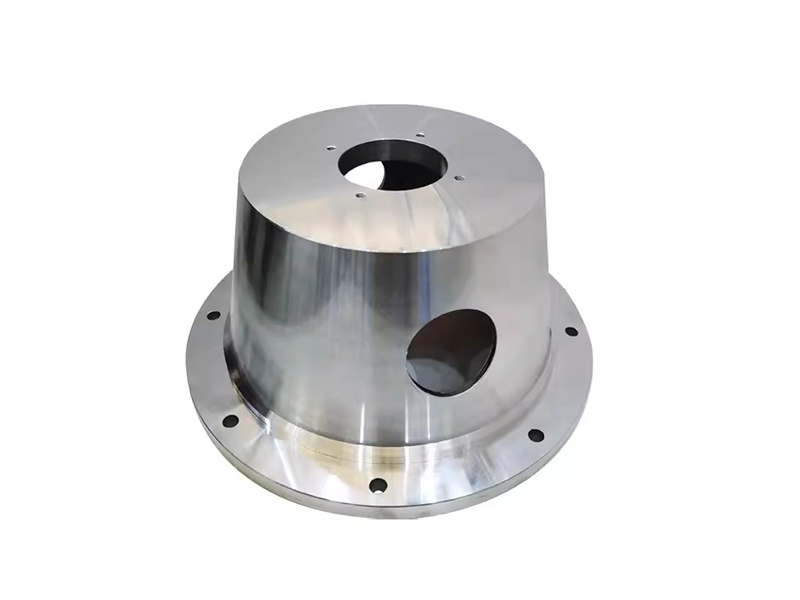

The hydraulic pump bell housing is a critical component that houses the hydraulic pump within an engine assembly. It serves as a protective cover and a mounting point for the hydraulic pump, ensuring proper alignment and operation. The design and construction of the bell housing can directly affect the performance of the hydraulic system.

2.2 The Role of Bell Housing in Hydraulic Systems

The bell housing plays a pivotal role in facilitating the optimal functioning of hydraulic systems. It ensures that the hydraulic pump operates efficiently by providing a stable environment for its components. Additionally, it helps in minimizing vibrations and noise, which can impact engine performance negatively.

3. Engine Efficiency: What Does It Mean?

3.1 Defining Engine Efficiency

**Engine efficiency** refers to the ability of an engine to convert fuel into usable energy. It is a measure of how effectively an engine performs its functions while minimizing waste. High engine efficiency translates to better fuel economy, reduced emissions, and enhanced overall vehicle performance.

3.2 Factors Influencing Engine Efficiency

Several factors influence engine efficiency, including:

- **Fuel Quality**: The type of fuel used can significantly impact combustion efficiency.

- **Engine Design**: The configuration of the engine, including its components, influences performance.

- **Maintenance**: Regular upkeep ensures that all parts function optimally.

- **Hydraulic System Functionality**: The efficiency of hydraulic components directly impacts engine performance.

4. The Relationship Between Hydraulic Pump Bell Housing and Engine Performance

4.1 How Bell Housing Affects Hydraulic Pump Functionality

The **hydraulic pump bell housing** is essential for the pump's operational efficiency. A properly designed bell housing ensures that the pump remains aligned and securely mounted, which minimizes the risk of failure due to vibration or misalignment. Furthermore, it aids in the smooth operation of hydraulic fluid circulation, leading to better performance.

4.2 The Impact on Engine Output and Fuel Efficiency

An efficient hydraulic pump contributes to enhanced engine output. When the hydraulic pump operates optimally, it aids in achieving smoother gear transitions and better control of hydraulic systems. This efficiency leads to improved fuel economy, as the engine does not have to work harder than necessary to perform its functions.

5. Maintenance Tips for Hydraulic Pump Bell Housing

5.1 Regular Inspections

Conducting regular inspections of the hydraulic pump bell housing is essential to ensure its integrity. Look for signs of wear, corrosion, or damage that could impede performance. Addressing these issues promptly can prevent more significant problems down the line.

5.2 Common Issues and Solutions

Some common issues associated with hydraulic pump bell housing include:

- **Leakage**: Regularly check for leaks that could signify a seal failure.

- **Corrosion**: Ensure that the housing is protected from rust and other forms of corrosion.

- **Vibrations**: Excessive vibrations can indicate misalignment or damage that needs to be corrected.

6. Upgrades and Innovations in Hydraulic Systems

6.1 Modern Materials and Technologies

Advancements in materials and manufacturing technologies have led to the development of more durable and efficient hydraulic pump bell housings. These innovations contribute to longer service life and improved performance, further enhancing engine efficiency.

6.2 The Future of Hydraulic Pump Bell Housing

As the automotive industry continues to evolve, so too will the technology surrounding hydraulic systems. Future trends may include the integration of smart sensors within bell housings to monitor performance in real-time, allowing for predictive maintenance and enhanced overall efficiency.

7. Conclusion

The relationship between hydraulic pump bell housing and engine efficiency is a critical yet often overlooked aspect of automotive performance. Understanding the role of the hydraulic pump bell housing can lead to better maintenance practices, improved vehicle performance, and enhanced fuel efficiency. As technology advances, the potential for further innovations in hydraulic systems will only strengthen this connection, paving the way for more efficient and powerful engines.

8. Frequently Asked Questions (FAQs)

What is the primary function of a hydraulic pump bell housing?

The primary function of a hydraulic pump bell housing is to house and protect the hydraulic pump, ensuring proper alignment and operation within the engine assembly.

How does the hydraulic pump influence engine efficiency?

The hydraulic pump affects engine efficiency by facilitating smooth operation of hydraulic systems, which contributes to better performance and fuel economy.

What maintenance practices should be followed for hydraulic pump bell housing?

Regular inspections, monitoring for leaks, and addressing signs of wear or corrosion are crucial maintenance practices for hydraulic pump bell housing.

How can modern technology improve hydraulic pump bell housing?

Modern technology can improve hydraulic pump bell housing by utilizing advanced materials for durability and incorporating smart sensors for performance monitoring.

What are the signs of a failing hydraulic pump bell housing?

Signs of a failing hydraulic pump bell housing include leaks, excessive vibrations, and reduced performance in hydraulic systems.

By understanding the intricate connection between hydraulic pump bell housing and engine efficiency, we can enhance automotive performance and longevity. Proper maintenance and awareness of this relationship are vital for any vehicle owner seeking to maximize efficiency.

Keywords:

You Can Also Learn More About Industry Trends