Understanding Oil Tank Manhole Covers: Essential Insights for Professionals in the Packaging Industry

Release Time:

Feb 12,2026

Oil tank manhole covers are essential components in various industrial settings, including those related to storage and transportation of oil and other liquids. These covers serve as protective seals for manholes, ensuring safety and compliance with industry regulations. While they might seem straightforward, understanding their design, function, and application is crucial, especially for professi

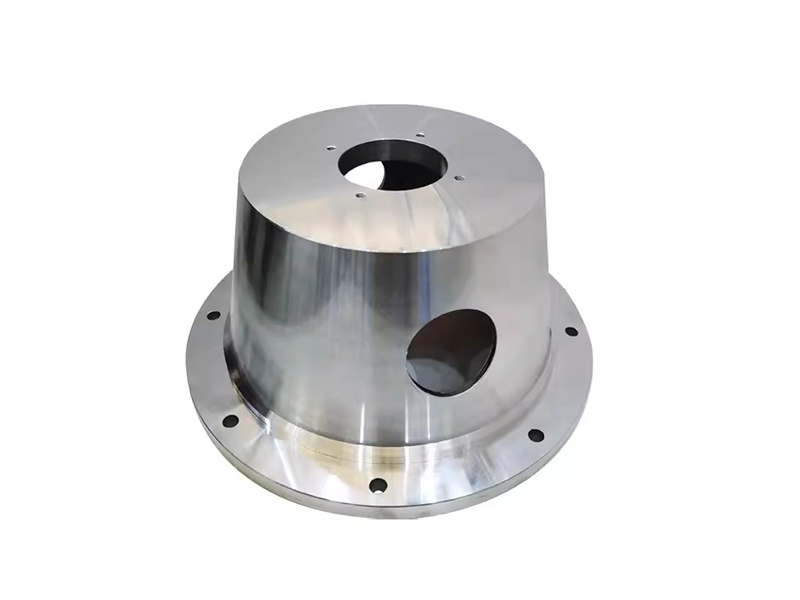

Oil tank manhole covers are essential components in various industrial settings, including those related to storage and transportation of oil and other liquids. These covers serve as protective seals for manholes, ensuring safety and compliance with industry regulations. While they might seem straightforward, understanding their design, function, and application is crucial, especially for professionals in the packaging and printing sectors.

Primarily, an oil tank manhole cover prevents unauthorized access and minimizes the risk of accidental spills or leaks. These covers are designed to withstand significant pressure and environmental factors, making them robust and reliable. For professionals in the packaging industry, the principles that govern the design and functionality of manhole covers can provide valuable insights into the development of secure packaging solutions.

The material used for oil tank manhole covers is typically steel or heavy-duty plastic, ensuring durability and resistance to corrosion. The choice of material is critical, as it impacts the cover's longevity and its ability to maintain a secure seal. Similarly, when designing packaging products, selecting the right materials is paramount to ensuring product safety and integrity.

In the context of the packaging industry, plastic closures that serve as bottle caps or container lids share some functional similarities with oil tank manhole covers. Both require tight sealing mechanisms to prevent leakage and maintain product quality. Understanding the engineering behind manhole covers can inspire innovative design approaches in developing packaging solutions that prioritize security and usability.

Furthermore, regular inspections and maintenance of oil tank manhole covers are essential for operational safety and efficiency. This aspect can also be mirrored in the packaging industry, where ensuring the integrity of packaging materials is vital. By adopting best practices for maintenance and quality control, packaging professionals can enhance their product offerings and meet regulatory standards.

In conclusion, while oil tank manhole covers may seem specific to the oil and gas industry, their concepts and practices offer valuable lessons for professionals in the packaging and printing sectors. Learning from the design and operational principles of these covers can lead to improved packaging solutions, reinforcing the importance of safety and quality in product packaging. By integrating these insights, businesses can enhance their product reliability and consumer trust, ultimately contributing to industry success.

For anyone interested in improving their packaging strategies, understanding related industrial components such as the oil tank manhole cover can provide a clearer perspective on product safety and durability.

Primarily, an oil tank manhole cover prevents unauthorized access and minimizes the risk of accidental spills or leaks. These covers are designed to withstand significant pressure and environmental factors, making them robust and reliable. For professionals in the packaging industry, the principles that govern the design and functionality of manhole covers can provide valuable insights into the development of secure packaging solutions.

The material used for oil tank manhole covers is typically steel or heavy-duty plastic, ensuring durability and resistance to corrosion. The choice of material is critical, as it impacts the cover's longevity and its ability to maintain a secure seal. Similarly, when designing packaging products, selecting the right materials is paramount to ensuring product safety and integrity.

In the context of the packaging industry, plastic closures that serve as bottle caps or container lids share some functional similarities with oil tank manhole covers. Both require tight sealing mechanisms to prevent leakage and maintain product quality. Understanding the engineering behind manhole covers can inspire innovative design approaches in developing packaging solutions that prioritize security and usability.

Furthermore, regular inspections and maintenance of oil tank manhole covers are essential for operational safety and efficiency. This aspect can also be mirrored in the packaging industry, where ensuring the integrity of packaging materials is vital. By adopting best practices for maintenance and quality control, packaging professionals can enhance their product offerings and meet regulatory standards.

In conclusion, while oil tank manhole covers may seem specific to the oil and gas industry, their concepts and practices offer valuable lessons for professionals in the packaging and printing sectors. Learning from the design and operational principles of these covers can lead to improved packaging solutions, reinforcing the importance of safety and quality in product packaging. By integrating these insights, businesses can enhance their product reliability and consumer trust, ultimately contributing to industry success.

For anyone interested in improving their packaging strategies, understanding related industrial components such as the oil tank manhole cover can provide a clearer perspective on product safety and durability.

Keywords:

You Can Also Learn More About Industry Trends